Custom CNC Machining Services

Get an instant quote today and order custom CNC machining services at a better price.

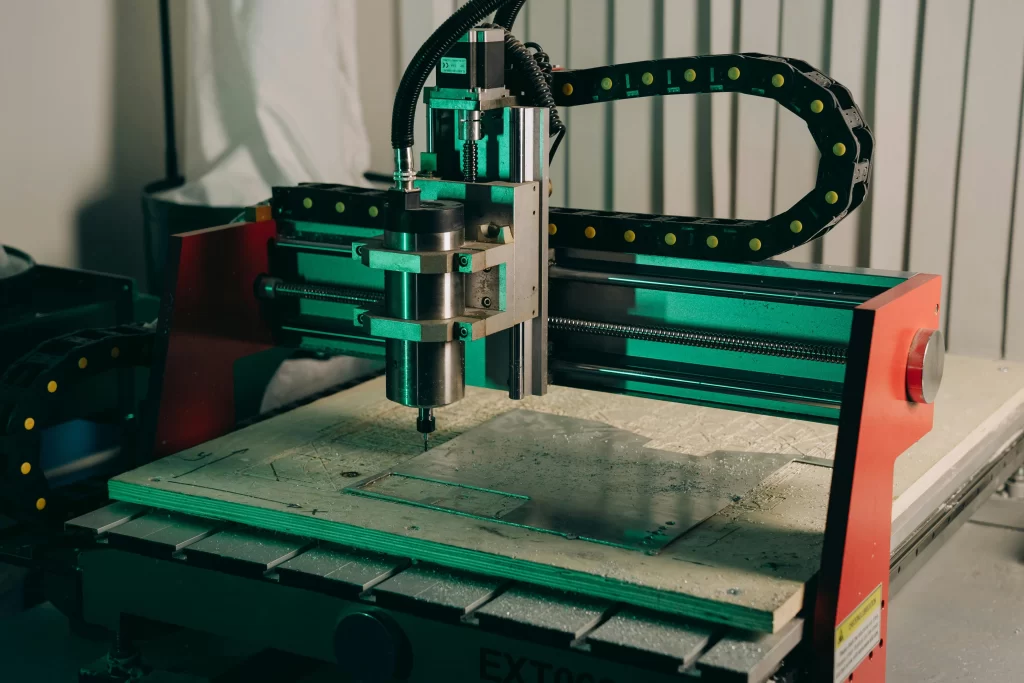

What is CNC Machining ?

CNC machining, also called lathe machining . CNC lathe is one of the more widely used CNC machine tools. It is mainly used for shaft parts or disk parts of the internal and external cylindrical surface, any cone angle of the internal and external conical surface, complex rotary internal and external surfaces and cylindrical, tapered threads and other cutting, and can be grooving, drilling, reaming, reaming and boring.

Characteristics of CNC Machining

Automatization

CNC machining automatically controls the movement of the machine tool through a computer program, reducing manual operation and improving productivity.

Highly Accurate

CNC machining enables high-precision machining and is suitable for the manufacture of parts with complex shapes and high requirements.

Dexterity

CNC machine tools can quickly change programs according to different machining needs, adapting to small batch diversified production.

Repeatable

CNC machining maintains consistent machining quality and is suitable for high volume production.

Reduction Of Manpower

Reduces reliance on operators, improves safety and reduces labor intensity for workers.

Economic Benefit

Despite the high initial investment, it can significantly reduce production costs and improve efficiency in the long run.

CNC Machining process

The CNC (Computer Numerical Control) machining process can typically be categorized into the following six steps, which cover the entire machining process from initial design to final product quality inspection, ensuring efficient and accurate part manufacturing.

- Design and modeling: using CAD software to determine the shape, size and details of the model.

- Generate G-code: Import CAD model into CAM software to generate G-code.

- Machine Preparation: Prepare the CNC machine and make sure it is in good working condition.

- Program loading: Upload the generated G-code to the CNC machine to ensure readiness.

- Machining execution: The machine is started and machining is performed according to G-code.

- Quality Inspection: Parts are inspected to ensure that they meet design requirements.

Materials we can make

CNC can play an important role in transportation parts, especially in the precision manufacturing of automotive parts, such as engine components and braking systems, as well as in automotive and motorcycle parts, such as motorcycle frames and engine components, to ensure the high precision and safety of these critical parts.

CNC has a wide range of applications in machinery and equipment parts, especially in the production of food machinery parts (e.g. knives and conveyor belts), textile machinery parts (e.g. bobbins and needleboards), woodworking machinery parts (e.g. cutting knives), as well as powder metallurgy parts, which enhances machining efficiency and product quality.

CNC can make a big difference in accessories for electronic and entertainment products, especially in the manufacture of housings and controllers for gaming machine accessories, as well as in the machining of home appliance accessories, such as housings and internal components, to ensure that the products look great and are fully functional.

CNC plays an important role in furniture and lock fittings, covering the manufacture of lock fittings (e.g. lock bodies and keys), office furniture (e.g. connectors and adjusters), and instrument parts, ensuring high precision and reliability for all types of products.

Our Capabilities

We have been manufacturing sintered metal parts for over a decade and our engineers are very experienced.

Our engineers will immediately review your uploaded files to provide an accurate quote for the project.

From sample production to full-scale production, we are able to fulfill both small and large orders.

We have a wide range of equipment and partners so that we can fulfill orders quickly, regardless of their volume or complexity.

Get a quote free

Contact Us

Need some customized parts? We will provide you with reliable solutions, from material selection to cost control, including but not limited to powder metallurgy products, MIM metal molding, CNC precision machining and more.