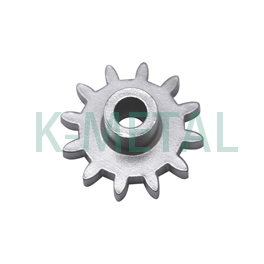

Customization of powder metallurgy stainless steel parts and iron-based parts

Material: 304L

Tensile strength: ≥ 500 MPa

Yield strength: ≥ 180 MPa

Hardness: ≥ 120 HV10

Density: ≥ 7.80 g/cm3

Process: Metal powder injection molding, MIM, powder metallurgy

Application: Electric tools, pneumatic tools

Metal Powder Injection Molding MIM Material List

| Performance | After sintering | Heat treatment | C% | NI% | Cr% | Mn% | Si% | Fe% |

|---|---|---|---|---|---|---|---|---|

| density | >7.80 g/cm3 | |||||||

| tensile strength | >500 mPa | <0.03 | 9-11 | 19-20 | <2.0 | <1.0 | ||

| hardness | >120 HV10 | |||||||

| Elongation rate | >50% | |||||||

| yield strength | >180 MPa |

Metal Powder Injection Molding MIM Dimensional Accuracy Table

Special tolerance requirements can be achieved through secondary machining, such as CNC, lathe, milling machine, etc

| size | General manufacturing tolerances | General situation | exceptional case |

|---|---|---|---|

| 1-4mm | +/-0.05 | +/-0.05 | +/-0.03 |

| 4-10mm | +/-0.10 | +/-0.07 | +/-0.05 |

| 10-20mm | +/-0.15 | +/-0.10 | +/-0.08 |

| 20-30mm | +/-0.25 | +/-0.15 | +/-0.10 |

| features | General scope | Special scope | |

| Part size | 0.2-50g | 0.09-200g | |

| wall thickness | 0.5mm or above | 0.25 or above |