Haas CNC Parts is a product of Haas Automation, Inc. known for its cost-effective, reliable and innovative CNC machine tool products. Below is a detailed description of Haas CNC Parts and its background.

Background On Haas CNC Parts

Haas CNC parts are the core components of Haas machine tools. Its design and manufacture are directly related to the performance, accuracy and reliability of the machine tool. The development and production of Haas parts is always guided by the following principles:

To meet the demands of modern manufacturing for precision machining.

Using high-quality materials and advanced technology to ensure long-term stable operation of parts in harsh environments.

Easy to install, maintain and replace, reducing downtime.

Constantly introducing new technologies, such as intelligent sensors, adaptive control systems, etc.

Main Categories And Functions

Machine Parts

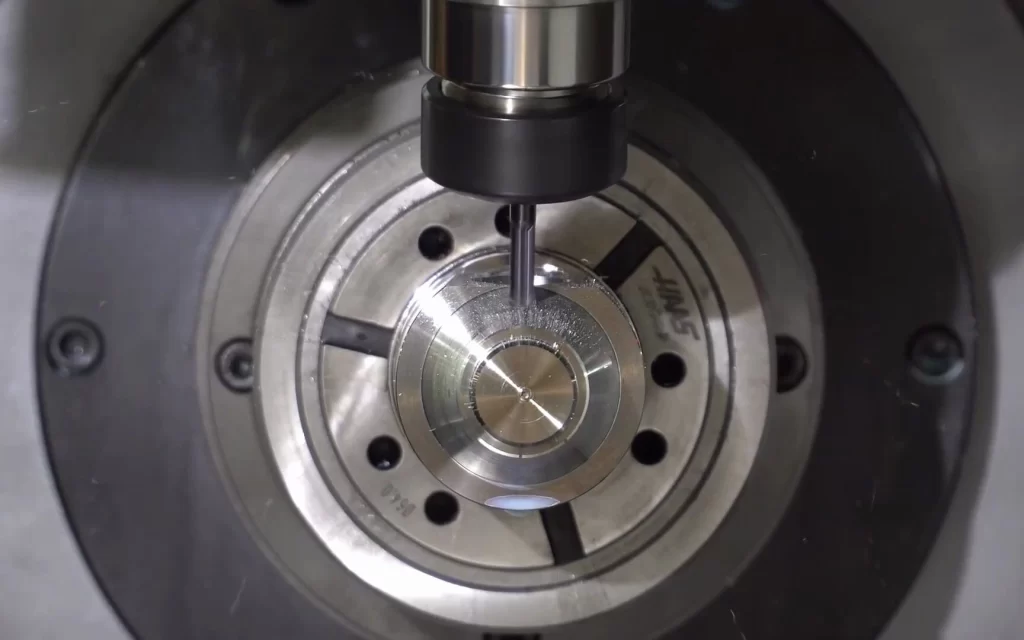

Spindle: The core component of a machine tool, responsible for driving the tool for cutting. Haas spindles are known for their high speed, high rigidity and low vibration.

Guideways And Screws: Used to realize high-precision movements of the machine’s axes. Haas uses linear guideways and ball screws to ensure smooth movement and positioning accuracy.

Tool Magazine: For storage and automatic tool change. Haas tool magazines are compactly designed for fast and reliable tool changes.

Bearings: Support the spindle and transmission parts to ensure the smoothness and precision of machine operation.

Electrical Parts

Servo Motors And Drives: Control the movement of each axis of the machine tool. Haas servo system is famous for its high response speed and stability.

CNC Controller: Haas self-developed control system with friendly interface and powerful functions, supporting multi-axis linkage and complex machining tasks.

Sensors: Used to monitor the status of the machine tool, such as temperature, vibration, tool wear, etc., to ensure the safety and stability of the machining process.

Auxiliary System

Cooling System: Used to cool the tool and workpiece to prevent overheating from affecting the machining quality.

Lubrication System: ensure the lubrication of the moving parts of the machine tool, reduce wear and prolong the service life.

Chip Conveyor: Automatically removes chips generated during machining to keep the working environment clean.

Technical Features of Haas CNC Parts

Advanced manufacturing processes such as precision grinding, heat treatment and surface coating are in use to manufacture Haas parts to ensure high precision and long life.

Some parts integrate sensors and IoT technology for real-time monitoring of operating conditions and feedback data to support predictive maintenance.

Standardization of part design facilitates quick replacement and upgrading, reducing downtime.

Haas parts design is energy efficient, reducing energy consumption and environmental impact.

Applications of Haas CNC Parts

Haas CNC parts are used in a wide range of manufacturing applications that require high precision and efficiency, including:

Machining complex shaped aerospace parts such as turbine blades, airframe structural parts.

Producing engine blocks, gearbox housings, chassis parts, etc.

Manufacturing high-precision injection molds, stamping dies, etc.

Processing surgical instruments, implants and medical equipment parts.

Manufacture precision electronic components and semiconductor equipment.

Market Advantages of Haas CNC Parts

Haas parts are known for their high cost performance, which can guarantee the quality and reduce the purchasing cost of users at the same time.

The company has established a comprehensive service network around the world to provide users with timely technical support and parts supply.

Every year they invest a lot of resources in research and development, and constantly introduce new technologies and products to meet the market demand.