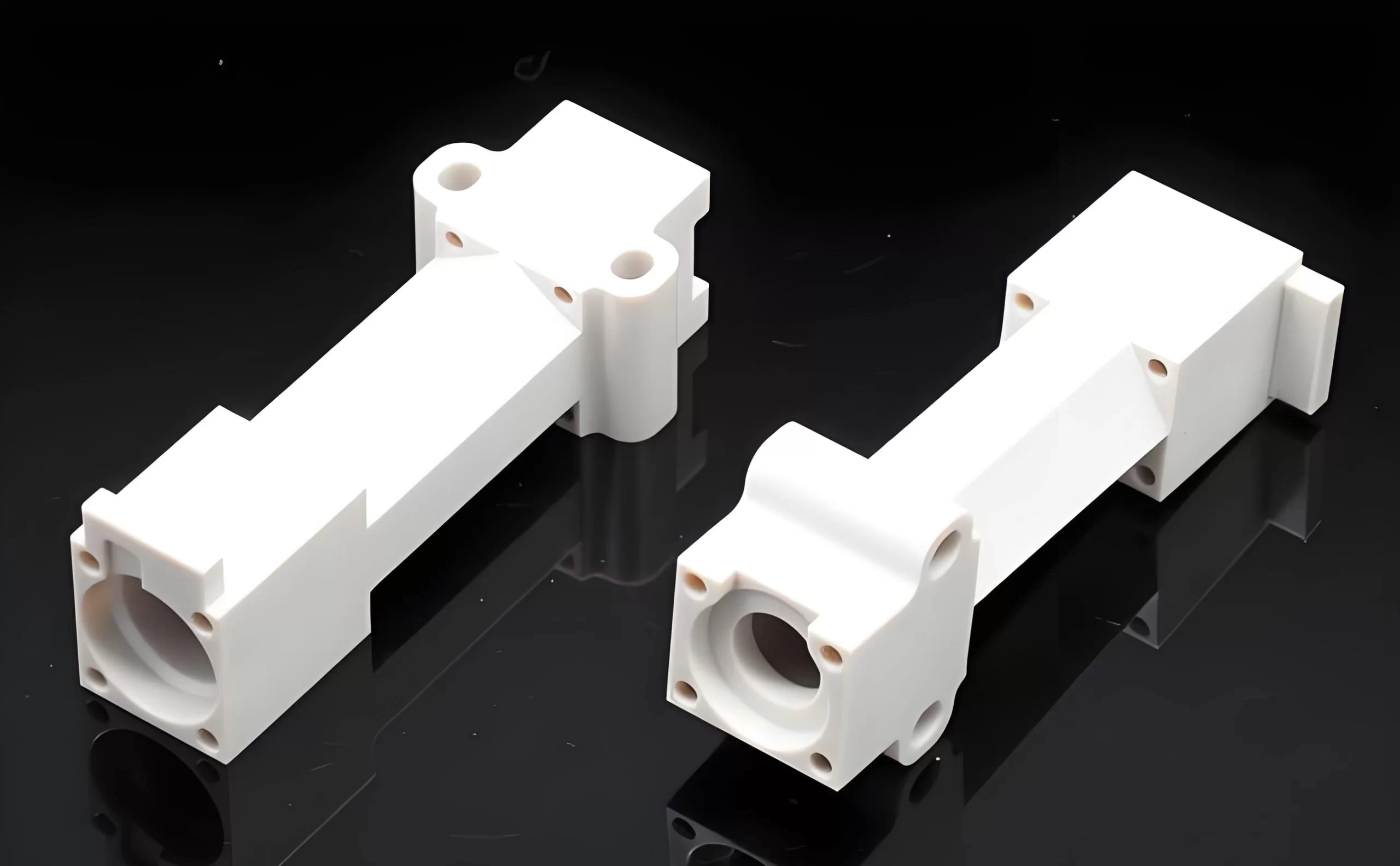

Machined Plastic Parts are parts that meet the requirements obtained by machining plastic raw materials through processes such as turning and milling. Similar to machined parts made of other materials, they are widely used in a variety of fields. They can fulfill different functional requirements.

Why Machined Plastic Parts?

Parts of various complex shapes and sizes can be processed according to specific design requirements. Can meet the special requirements of different application scenarios.

Compared with metal materials, machined plastic parts can significantly reduce the weight of equipment or products. It is important in aerospace, automotive and other weight-sensitive areas.

Most plastics have excellent corrosion resistance and are able to maintain good performance in harsh environments such as moisture, acids and alkalis. This results in reduced maintenance and replacement costs for parts.

The price of plastic raw materials is relatively low, and the machining process is relatively simple and highly productive. Therefore, the manufacturing cost of machined plastic parts is usually lower than that of metal parts.

Materials of Machined Plastic Parts

Polycarbonate(PC):

High transparency, high strength, good impact resistance and heat resistance. Commonly used in the manufacture of parts requiring transparency and mechanical strength, such as optical lenses, protective masks.

Polyamide(PA):

Commonly known as nylon, with good wear resistance, self-lubricating, corrosion resistance and high mechanical strength. Suitable for the manufacture of gears, bearings, sliders and other mechanical parts.

Polytetrafluoroethylene(PTFE):

Has a very low coefficient of friction, good chemical stability and high temperature resistance. Often used in the manufacture of parts that require low friction and corrosion resistance. Such as seals, gaskets, pipe linings, etc..

Acrylonitrile-butadiene-styrene copolymer(ABS):

Good overall performance, with high strength, hardness, impact resistance and good processing performance. Since its surface is easy to paint and print, it is widely used in the shell and parts manufacturing of electronic and electrical appliances, automobiles, toys and other industries.

Machined Plastic Parts Supplier

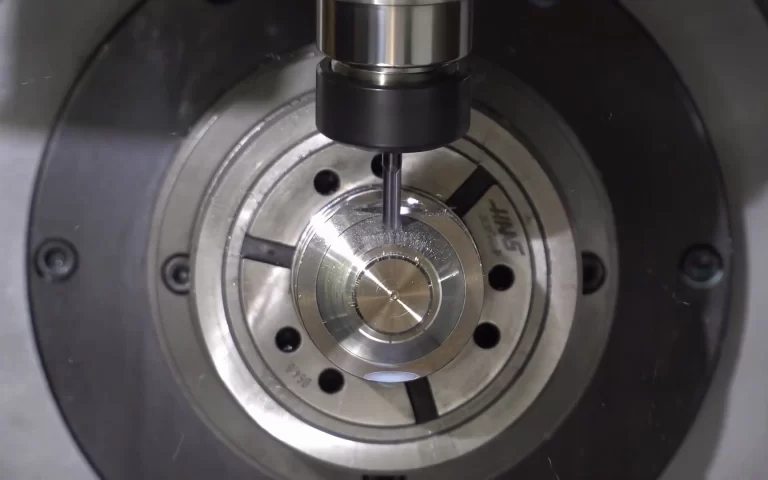

Machining Process

Turning:

Processing of rotary parts, such as cylindrical, conical, threaded and other shaped plastic parts. The workpiece is rotated by the spindle of the lathe and the tool cuts along the axial or radial direction of the workpiece. This removes excess material and achieves the desired shape and size.

Milling:

Using a milling cutter to cut plastic workpieces on a milling machine, a variety of complex shapes can be machined. Milling processing is MORE FLEXIBLE and can realize many different processing requirements.

Drilling:

It is a common machining process to use drills to process holes of various diameters in plastic workpieces. It can realize the functions of fluid channels and electrical circuits between parts.

Grinding:

Used for high-precision surface machining of plastic parts to obtain good surface finish and dimensional accuracy. Commonly used for processing parts that require high precision fit, such as molds, optical components, etc.

Application Fields

| Application Fields | Examples | ||

|---|---|---|---|

| Aeroespacial | Plastic Parts Of Seats | Ventilation Ducts | Dashboard Frames |

| Automotive Manufacturing | Dashboards | Door Interior Panels | Intake Manifolds |

| Electronics and Electrical Appliances | Computer Cases | Mobile Phone Cases | Electronic Connectors |

| Medical Equipment | Medical syringes | Components Of Inspection Equipment | Handles Of Surgical Instruments |

| Industrial Equipment | Industrial Gears | Conveyor Belt Rollers | Equipment Protective Covers |

| Daily Necessities | Plastic Furniture | Toys | Kitchen Utensils |

| Construction and Building Materials | Plastic Pipes | Components Of Plastic – Steel Doors And Windows | Decorative Lines |