An oil bearing sleeve is a critical component. It’s a self-lubricating bushing. It ensures smooth, low-friction operation in various machinery. For engineers, manufacturers, and industrial buyers, understanding these sleeves is key. Discover how superior sleeves enhance equipment reliability and longevity.

Why Oil Bearing Sleeves Are Indispensable

Oil bearing sleeves are fundamental to efficient mechanical systems. They provide continuous lubrication. This minimizes wear and heat generation.

Sleeves contain impregnated oil. They release it during operation. This eliminates external greasing needs.

The oil film minimizes contact. This significantly lowers operational friction. It ensures smooth, effortless motion.

Less friction means less wear. Components last much longer. This reduces maintenance and replacement costs.

Friction reduction also minimizes noise. This creates a quieter working environment. It improves overall machinery acoustics.

Self-lubricating properties save time and money. No regular lubrication is needed. This lowers ongoing operational expenses.

Qué hacemos

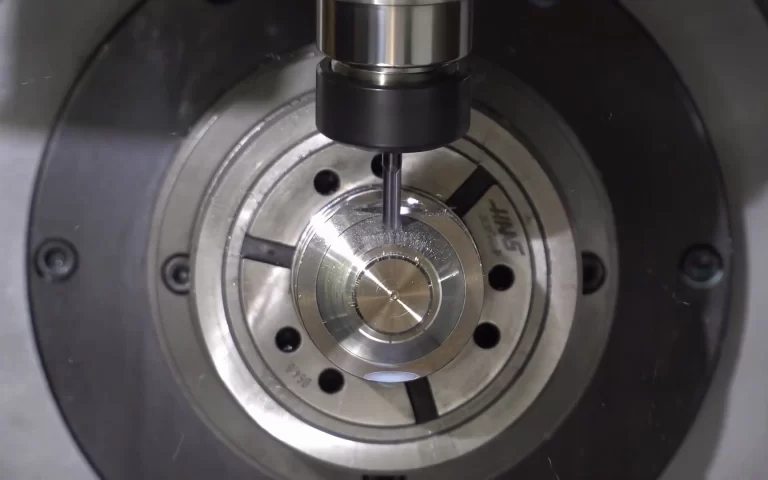

Manufacturing Oil Bearing Sleeves

| Método | Ventajas | Materiales | Best For |

|---|---|---|---|

| Metal sinterizado | Self-Lubricating, Volume | Bronze, Iron, Copper-Steel | High Volume, Porous |

| CNC | High Precision, Custom | Brass, Bronze, Plastic | Prototypes, Specific Fits |

| MIM | Complex Shapes, Volume | SS, Bronze, Iron | Intricate, High Volume |

Common Materials

| Material | Properties | Common Uses | Notes |

|---|---|---|---|

| Bronce sinterizado | Porous, Self-Lubricating | Motors, Appliances | Excellent Friction |

| Hierro sinterizado | Strong, Cost-Effective | General Industrial | Good for Higher Loads |

| Sintered Copper-Steel | Strong, Conductive | Automotive, Heavy Duty | High Load Capacity |

| Brass (Solid) | Machinable, Durable | Pumps, Valves | Requires External Lube |

| Plastic (e.g., PTFE, Nylon) | Low Friction, Lightweight | Light Duty, Specific Apps | No External Lube |

Why Quality Oil Bearing Sleeves Drive Operational Success

The quality of your oil bearing sleeve directly impacts machine uptime. Substandard sleeves can lead to premature failure. They might seize or wear out quickly. This causes costly downtime and repairs. High-quality sleeves ensure reliable, continuous operation. They provide superior wear resistance and lubrication. Investing in quality components maximizes your equipment’s productivity.

Selecting the Ideal Oil Bearing Sleeve for Your Application

Consider your specific operational needs when choosing an oil bearing sleeve. Evaluate the required load capacity, speed, and environmental conditions. For continuous, high-performance applications, sintered bronze or iron-based alloys are often ideal. For lighter duties or specific chemical resistance, engineered plastics might suffice. Always ensure the sleeve’s dimensions and porosity match your system.

You can Contacto and let us make the BEST CHOICE for you.

- Teléfono: 0086 – 577 – 8551 1172

- Correo electrónico: [email protected]

¡Sólo necesitamos un par de horas!

Envíenos un mensaje si tiene alguna pregunta o solicite un presupuesto. Nuestros expertos le darán una respuesta en 24 horas y le ayudarán a seleccionar el producto adecuado que necesita.