Sintered iron is a basic material for powder metallurgy. It is made by compacting polvo de hierro and then heating it. This process creates strong, often porous parts. Find out how sintered iron can optimise cost and performance in a variety of applications.

Why Sintered Iron is Essential

It offers significant advantages for numerous industrial applications. Its unique properties lead to efficient and durable parts.

Sintering minimizes material waste. It also reduces machining steps. This significantly lowers overall part cost.

Sintered iron provides excellent strength. It can be lighter than cast iron. This improves component efficiency.

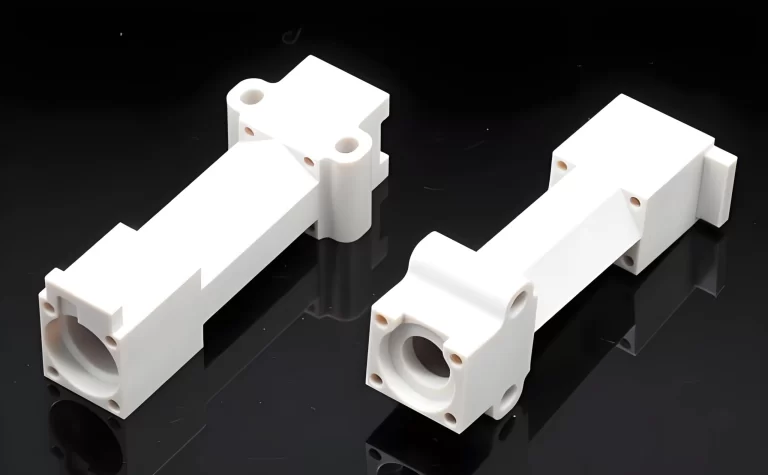

Powder metallurgy allows intricate designs. Near net-shape parts are common. This reduces secondary operations.

Iron’s natural hardness provides durability. It resists abrasion well. This extends part lifespan.

It’s used in automotive, appliances, and tools. Sintered iron adapts to many needs. This makes it a broad solution.

Qué hacemos

Sintered Iron in Manufacturing: A Comparative Look

| Método | Ventajas | Materiales | Best For |

|---|---|---|---|

| Metal sinterizado | Cost-Effective, Porous | Iron, Bronze, Copper-Steel | High Volume, Complex |

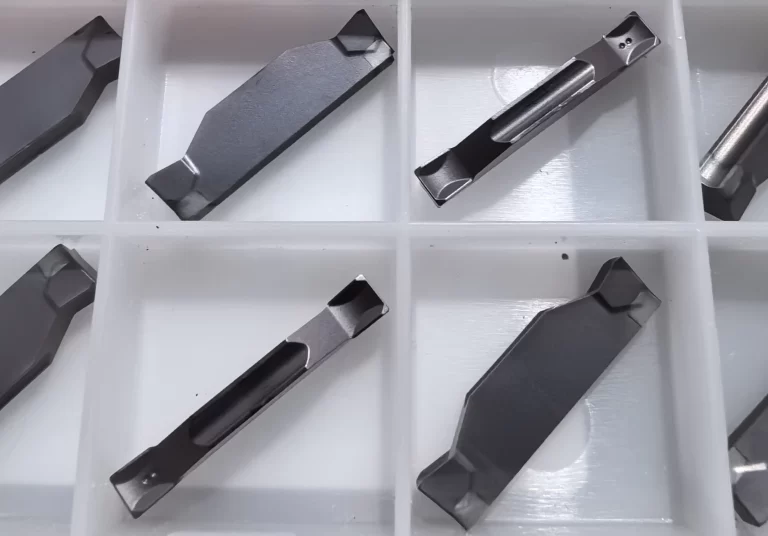

| CNC | Precision, Custom | Solid Steel, Cast Iron | Low Volume, Non-Porous |

| MIM | Complex, High Volume | SS, Low Alloy Steels | Intricate, Dense Parts |

Properties of Sintered Iron Components

| Propiedad | Descripción | Benefits | Notes |

|---|---|---|---|

| Density | Customizable | Strength, Porosity | Affects hardness, self-lube |

| Hardness | Moderate to High | Wear Resistance | Enhanced by heat treatment |

| Tensile Strength | Bien | Load Bearing | Suitable for structural parts |

| Relación coste-eficacia | Low Raw Material Use | Reduced Production Cost | Ideal for mass production |

Why It Drives Industrial Advantage

The quality of your sintered iron components directly impacts product reliability. Substandard iron can lead to premature failure. It might lack strength or wear too quickly. This results in costly repairs and lost productivity. High-quality sintered iron ensures consistent, durable performance. It provides superior strength and wear resistance. Investing in quality maximizes your product’s lifecycle and customer satisfaction.

- Teléfono: 0086 – 577 – 8551 1172

- Correo electrónico: [email protected]

¡Sólo necesitamos un par de horas!

Envíenos un mensaje si tiene alguna pregunta o solicite un presupuesto. Nuestros expertos le darán una respuesta en 24 horas y le ayudarán a seleccionar el producto adecuado que necesita.