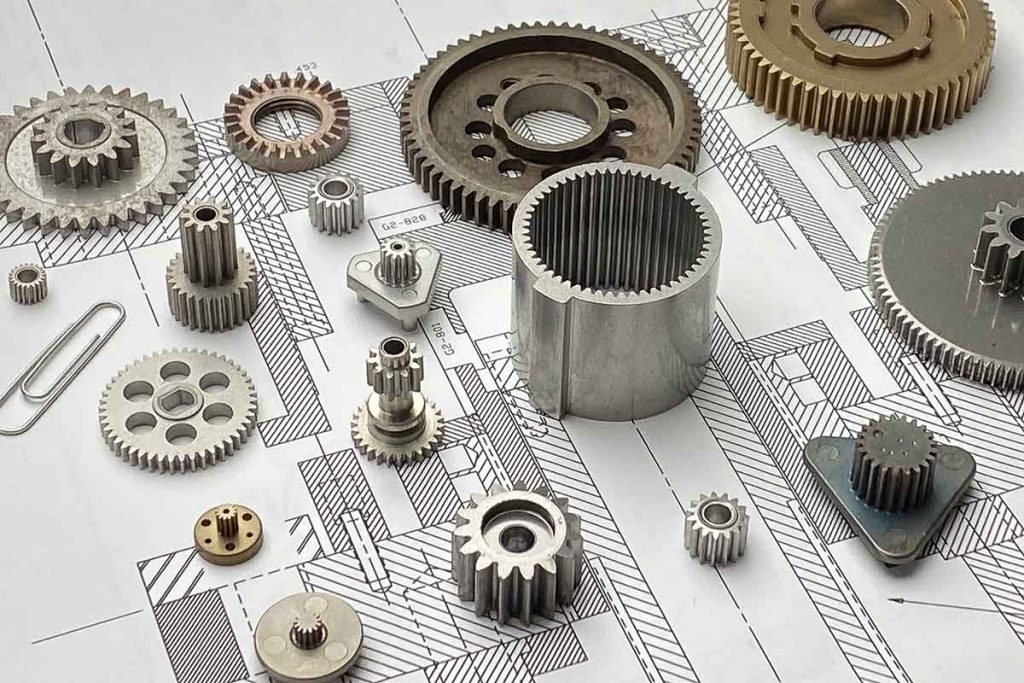

Customized Sintered Metal Parts Manufacturing

What is Sintered Metal Parts?

Sintered metal parts are mainly made of metal powder and non-metallic raw materials, through pressing, forming, sintering, shaping and other processes. Sintered metal parts have a certain dimensional accuracy, and can withstand tensile, compressive, twisting and other loads, and can work under friction and wear conditions, it also known as powder metallurgy products.

Characteristics of Sintered Metal Parts

Complex Shape Manufacturing

The sintering process allows for the manufacture of complex shaped parts, especially those that are difficult to produce through traditional casting or lathe machining .

Great Mechanical Properties

Sintered metal parts have a high mechanical hardness and are suitable for applications requiring high wear resistance and load carrying capacity.

Uniform Structure

The homogeneous bonding between metal powders during sintering contributes to the formation of consistent material properties and structure.

Low Cost for Volumn Quantity

Compared to conventional CNC machining parts, sintered metal parts can reduce the costs in some cases and minimize material waste and process steps, especially for mass-produced parts.

Resistant To Heat And Corrosion

Sintered metal parts have a good resistance to high temperatures and corrosion under the right conditions. This depends on the metal powder used and the specific parameters of the sintering process.

Special Alloys And Materials

By adjusting the composition of the powder, a variety of specialized metal alloys and composites can be manufactured to meet specific performance requirements.

Process of Sintered Metal Parts

The process of sintered metal parts involves pressing metal powders into shape and then heating them at high temperatures to bond the particles into a strong whole.The process of sintering metals can be divided into the following main steps:

- Preparation of powders: grinding of metallic materials, addition of other additives.

- Mixing: Mix the metal powder with other necessary additives to ensure homogeneity.

- Molding: The mixed powder is pressed into the desired shape and then cold pressed.

- Sintering: The molded blanks are heated in a special furnace to form a dense solid.

- Cooling: Cooling the material under controlled conditions to prevent internal stresses and cracks.

- Processing (if required): Post-processing work to meet final requirements.

Materials We Make

Iron powder has high density, high hardness and good abrasion resistance, which is used to manufacture various mechanical parts and tools, automobile parts, household appliance parts and so on.

Sintered Bronze / Brass powder is commonly used in the electronics industry and machinery manufacturing due to its good electrical and thermal conductivity.

Stainless steel powder metallurgy has high density and uniform structure, with good mechanical properties and chemical stability. In particular, stainless steel itself has good corrosion resistance, and the powder metallurgy process can further improve its corrosion resistance. This is because the organisational structure of sintered metal parts is uniform, reducing the possibility of local corrosion, and can be enhanced by adding specific alloying elements to enhance its corrosion resistance.

Titanium itself has the characteristics of high strength and high toughness, through the powder metallurgy process can make titanium sintered parts grain refinement, organisation uniformity, to further improve its mechanical properties, tensile strength, yield strength and other indicators of outstanding performance, applicable to the material strength requirements of higher occasions, such as aerospace, high-end machinery manufacturing and other fields.

Titanium has excellent biocompatibility, good affinity with human tissues, will not cause allergies, rejection and other adverse reactions, so it has high application value in medical devices, artificial joints, dental implants and other biomedical fields.

Tungsten is one of the hardest elements in metals, with a melting point of 3410°C. It has good electrical and thermal conductivity. Sintered Tungsten products made through the powder metallurgy process have extremely high hardness, enabling them to maintain good shape and dimensional stability under high wear and stress environments, can be used in high-temperature furnaces, aerospace engine, hot work moulds and other areas where high temperature resistance is required.

Aluminum powder has the advantages of low density, poor thermal conductivity, good plasticity, etc. It is mainly used in the aerospace field, such as aircraft engines, fuel systems, etc., as well as in the field of automobile manufacturing, such as engines, transmission systems, etc.

Magnesium powder has light weight, high strength and good corrosion resistance, and is mainly used in aerospace, automobile manufacturing and electronics industries.

Наши возможности

We have been manufacturing sintered metal parts for over a decade and our engineers are very experienced. We are adept at dealing with a wide range of complex workpieces and providing solutions for our customers.

Наши инженеры немедленно просмотрят загруженные вами файлы, чтобы предоставить точную смету на проект.

От изготовления образцов до полномасштабного производства, мы можем выполнять как небольшие, так и крупные заказы.

Мы располагаем широким спектром оборудования и партнеров, что позволяет нам быстро выполнять заказы, независимо от их объема и сложности.

We offer a full range of services from the production of sintered metal parts to shipping, and we are constantly looking to help our customers reduce their costs.

Applications of Sintered Metal Parts

Sintered metal parts are widely used in automotive manufacturing, machinery and equipment, home appliances and electronics, hardware tools, weaponry and other fields due to their advantages of bulk manufacturing, high precision, high performance and low cost. Especially for automobile manufacturing, the products are widely used in engine valve seats, valve guides, VCT system parts, sprockets, gears, valve guides and so on.

Machinery & equipment

Automobile

Home Appliances

Hardware Locks

Получите бесплатную цитату

Свяжитесь с нами

Нужны детали по индивидуальному заказу? Мы предоставим вам надежные решения, от выбора материала до контроля затрат, включая, но не ограничиваясь, порошковую металлургию, литье металлов по технологии MIM, прецизионную обработку с ЧПУ и многое другое.