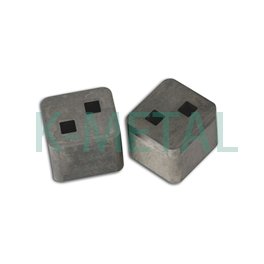

Shenzhen powder injection molding hard alloy

Material: Tungsten carbide (WC)

Hardness: HRC70-80

Density: ≥ 14.7g/cm3

Process: Metal powder injection molding, MIM, powder metallurgy

Application: Wear resistant parts, counterweight parts, etc

Metal Powder Injection Molding MIM Dimensional Accuracy Table

Special tolerance requirements can be achieved through secondary machining, such as CNC, lathe, milling machine, etc

| size | General manufacturing tolerances | General situation | exceptional case |

|---|---|---|---|

| 1-4mm | +/-0.05 | +/-0.05 | +/-0.03 |

| 4-10mm | +/-0.10 | +/-0.07 | +/-0.05 |

| 10-20mm | +/-0.15 | +/-0.10 | +/-0.08 |

| 20-30mm | +/-0.25 | +/-0.15 | +/-0.10 |

| features | General scope | Special scope | |

| Part size | 0.2-50g | 0.09-200g | |

| wall thickness | 0.5mm or above | 0.25 or above |