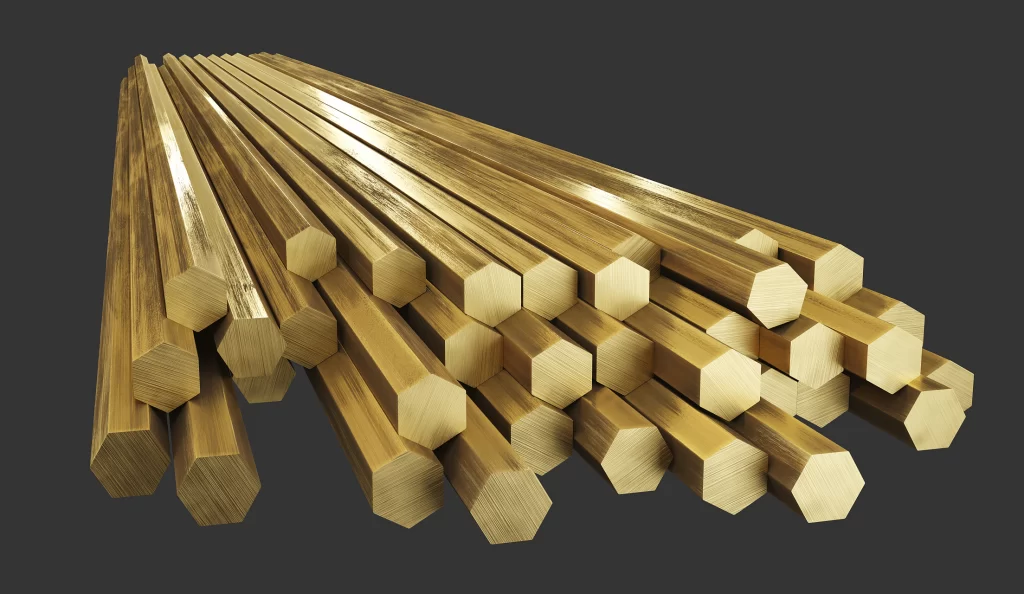

Sintered brass is a versatile material. It’s produced from brass powder. This process creates parts with unique properties and shapes. It’s widely used in diverse industries. For manufacturers and engineers, understanding its capabilities is crucial. Discover how sintered brass optimizes performance and production.

Why Sintered Brass is Indispensable

Sintered brass offers significant advantages for numerous mechanical and decorative applications. Its inherent properties lead to efficient and reliable components.

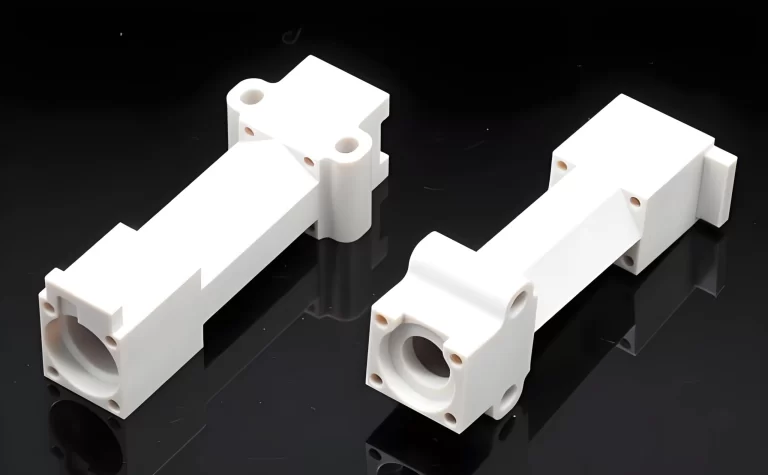

Sintering allows intricate part designs. Near net-shape production is common. This reduces secondary machining needs.

Brass offers natural lubricity. Sintered parts provide excellent durability. This extends component lifespan.

Brass inherently resists rust. Sintered forms maintain this property. It’s ideal for challenging environments.

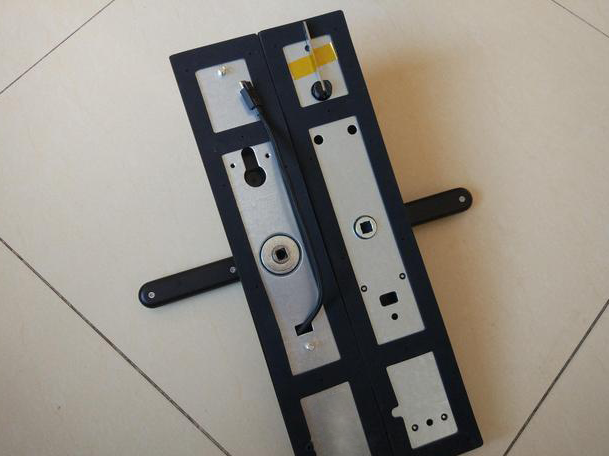

Brass provides a classic, attractive finish. Sintered parts can be plated or polished. This enhances product appearance.

Powder metallurgy minimizes material waste. It offers high volume production. This significantly lowers unit costs.

What We Do

Sintered Brass in Manufacturing: A Comparative Look

| Method | Advantages | Materials | Best For |

|---|---|---|---|

| Sintered Metal | Complex, Porous, Volume | Brass, Bronze, Iron | Gears, Bushings, Filters |

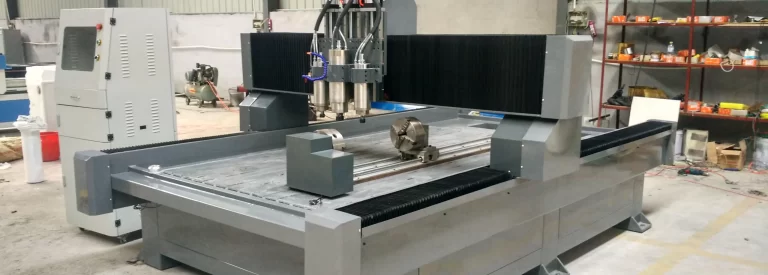

| CNC | Precision, Custom | Solid Brass, Aluminum | Prototypes, High-End |

| MIM | Intricate, High Volume | Brass Alloys, SS, Iron | Very Small, Complex, Dense |

Properties of Sintered Brass Components

| Property | Description | Benefits | Notes |

|---|---|---|---|

| Machinability | Good | Easy Finishing | Reduces post-processing |

| Porosity Control | Customizable | Filters, Self-Lube | Tailored to application |

| Corrosion Resistance | Excellent | Durable in Environments | Ideal for fluid contact |

| Dimensional Stability | High | Precise Fit | Ensures consistent parts |

Why It Drives Product Excellence

The quality of your sintered brass components directly impacts product reliability. Substandard brass can lead to premature wear. It might corrode or fail unexpectedly. This results in costly returns and lost reputation. High-quality sintered brass ensures consistent, long-term performance. It provides superior wear and corrosion resistance. Investing in quality maximizes your product’s durability and market appeal.

- Phone: 0086 – 577 – 8551 1172

- E-mail: [email protected]

We just need a couple of hours!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right product you need.