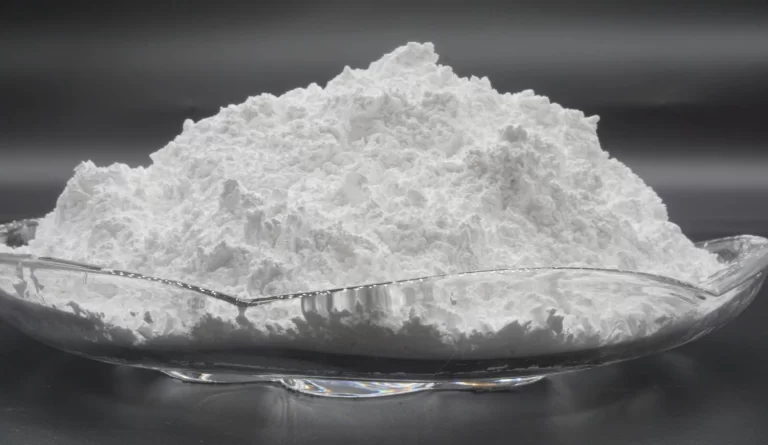

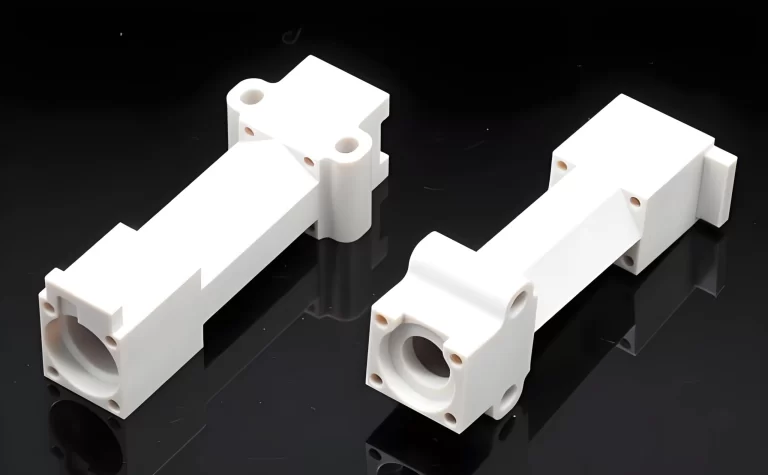

Sintered plastic is an amazing material. It is made by melting plastic powder. This produces porous, permeable parts. It has unique properties and a wide range of applications. It is vital for manufacturers and engineers to understand its benefits. Find out how sintered plastics can optimise performance and design.

Why Sintered Plastic is Indispensable

Sintered plastic offers significant advantages for numerous industrial and consumer applications. Its inherent properties lead to efficient and durable parts.

Sintering creates precise pore structures. This is ideal for filtration or wicking. It offers exceptional design flexibility.

Plastic components are naturally lighter. This reduces overall product weight. It improves energy efficiency.

Plastics are highly resistant to chemicals. They withstand harsh environments. This ensures long-term durability.

Some sintered plastics can incorporate lubricants. They provide smooth, low-friction operation. This reduces maintenance needs.

Porous structures can absorb sound. This reduces noise pollution. It improves acoustic performance.

What We Do

Sintered Plastic in Manufacturing: A Comparative Look

| Method | Advantages | Materials | Best For |

|---|---|---|---|

| Sintered Metal | Porous, Lightweight, Volume | PE, PP, PTFE, UHMW-PE | Filters, Wicks, Vents |

| CNC | Precision, Custom | Solid Plastics (Nylon, Delrin) | Prototypes, Non-Porous Parts |

| MIM | High Volume, Complex | ABS, Polycarbonate, Nylon | Dense, Complex Parts |

Properties of Sintered Plastic Components

| Property | Description | Benefits | Notes |

|---|---|---|---|

| Pore Size | Customizable | Filtration Efficiency | Critical for flow control |

| Chemical Resistance | High | Durable in Harsh Media | Broad compatibility |

| Lightweight | Low Density | Reduced Mass | Improves energy efficiency |

| Self-Lubrication | Some grades | Low Friction | Reduces wear, maintenance |

Why It Drives Innovation

The quality of sintered plastic components directly affects the reliability of the product. Substandard plastic can result in inconsistent porosity. It may fail under chemical exposure or pressure. This leads to product failure and recalls. High-quality sintered plastic ensures consistent performance and durability. It also provides excellent filtration, wicking or venting capabilities. Investing in quality components maximises product efficiency and longevity.

- Phone: 0086 – 577 – 8551 1172

- E-mail: [email protected]

We just need a couple of hours!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right product you need.