CNC Stainless Steel brings durability and precision to manufacturing. It shapes robust parts for critical industries. This article explores its process, benefits, materials, and applications. See why it matters.

What Does It Mean?

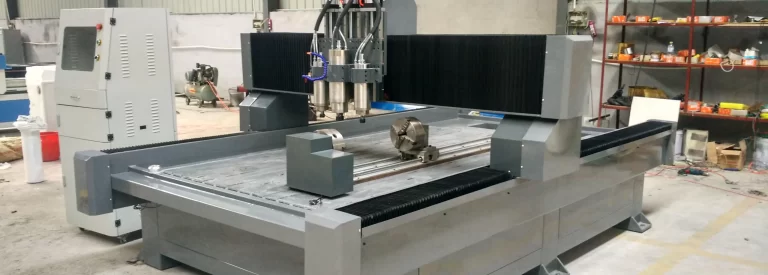

CNC stainless steel refers to stainless steel shaped by CNC machines. These machines cut, mill, and drill with precision. Stainless steel resists rust and wear. It suits tough environments. CNC ensures every part meets exact specs.

How Does It Work?

| Step | Action |

|---|---|

| Design | Draw a model in CAD software |

| Programming | Turn design into G-code |

| Machining | CNC machine shapes the steel |

| Finishing | Polish or coat for protection |

What We Do

Standards for CNC Stainless Steel

| Standard | Purpose | Industry |

|---|---|---|

| ISO 9001 | Guarantees consistent quality | General |

| AS9100 | Ensures aerospace safety | Aerospace |

| ISO 13485 | Confirms medical device standards | Medical |

Top Benefits of CNC Stainless Steel

Stainless steel resists corrosion in wet or harsh conditions. Stainless steel components last longer in harsh environments.

CNC machines meet tight tolerances every time. The parts are perfectly matched to complex systems.

Stainless steel can withstand heavy loads without breaking. CNC stainless steel parts ensure reliable performance under pressure.

Smooth surface after polishing. Parts look professional and wear-resistant.

Materials and Their Applications

| Steel Grade | Part | Application |

|---|---|---|

| 304 Stainless | Valves | Medical |

| 316 Stainless | Gears | Aerospace |

| 17-4 PH | Fasteners | Automotive |

| 410 Stainless | Blades | Machinery |

Global Impact of CNC Stainless Steel

CNC stainless steel has shaped industries across the globe. It supports medical advances with reliable tools. The aerospace industry benefits from durable jet components. The automotive industry improves efficiency with robust components. Plus, it meets global demand and drives economic growth.

CNC Stainless Steel FAQs

The stainless steel parts require careful care to perform at their best. Wash with mild soap to remove debris. Avoid harsh chemicals that can damage the finish. Also, check for wear and tear on a regular basis. Lubricate moving parts such as gears to minimize friction. Proper maintenance will extend their life.

316 stainless steel costs more than 304 stainless steel. Machining time and tool wear on complex parts can add to the cost. However, volume orders usually reduce the cost per part.

The sharp edges on the parts may cause cuts, so wear gloves when handling. Dust from processing may irritate the lungs, so use a mask. Furthermore, secure heavy parts to prevent them from falling. Safety ensures smooth operation.

- Phone: 0086 – 577 – 8551 1172

- E-mail: [email protected]

We just need a couple of hours!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right product you need.